Welcome to a presentation

on Six SigmaTM

2002年1月12日

What are your Expectations?

I would like to capture your expectations for the day?

Agenda

Introduction & overview

Demystifying Six Sigma

Creating the Six Sigma Culture

Managing the six sigma culture

Total cycle Time Reduction

Success Examples Around the world

How to Implement Six Sigma in your business

Q & A

Closing comments

Alliance Partnerships

MASET, LLC.

and

Motorola

Maset areas of expertise

Quality(Six Sigma)

Cycle time eduction

Leadership

Cultural change

Project Management

Supply chain Management

Facilitation

Training

Demystifying Six Sigma

What does Six Sigma mean to you

?

Many different definitions exist.I will try to address three this morning

Six sigma as a statistical term

Normal Distribution

Standard deviation

Six sigam as a statistical term

Values of a standard deviation

one sigma = 68.27 % 317,311 ppm

two sigma = 95.45 % 45,500 ppm

three sigma = 99.73 % 27,000 ppm

six sigma = 99.999999 % 1.96 ppb

Six sigma as a quality term

Invented by motorola in the mid 80’s

Service marked and registered by Motorola

Accepted by all countries

Accepted by all organization

Six sigma as a quality term

Six Sigma

=

3.4 ppm defective

Six sigma is a way to change an organizations culture

Provides a means of delivering

Total customer satisfaction

Focuses everyone in the organization on the same objective

Definition of defect

Defect are good!

“Associates need to feel comfortable in identifying and reporting defects.”

The effects of defects

Every occurrence of a defect within the process requires time to inspect,fix,and re-inspect.

Average cycle time is directly proportional to the total number of defects in the process.

Welcome to

Motorola’s

Quality Story

Culture

Culture guides the enterprise’s Day-To-Day behavior

The nature of culture

Culture provides its members with guidelines for dealing with just about everything

Much of every culture is cvert and implicit largely submerged like an iceberg

Cultures are constantly changing and evolving.

When culture and strategy clash,invariably culture wins out.

If the organizational culture does not embrac initiatives related to change,overall change efforts will fail

There is no such thing as “We’re different”

Functions in a typical organization

Accounting

Advertising

Distribution

Energy management

Environmental affairs

External affairs

Facilities

Finance

Health & safety

Human resources

legal

Manufacturing

Marketing

Profuct/service development

Payroll

Purchasing

Sales

Scheduling

Training

Transportation

Travel

The evolution of motorola’s quality culuture

Evolution continues!

Evolution continues!

How many objectives are there in your organization?

Our fundamental objective

Total customer satisfaction

Key beilfes

How we will always act

Key goals

What we must accomplish

Key initiatives

How we will do it

KEY INITATIVES

how we will do it

• Six sigma quality

• total cycle time reduction

• product manufaction and environmental leadership

• Prfit improvement

• Empowerment for all in a participative

Cooperative and creatice workplace

Consistent focus

Card created & adopted 1986

Five minor changes in1992

No significant changes during five different chairman

Bob Galvin

George Fisher

Bill Wiese

Gary Tooker

Chris Galvin

Creating and managing the Six Sigma quality culture

Sis sigma quality

One of the two key drivers of

increased

Total customer satisfation

and

reduced cost

Product/Service is delivered when promised

Every occurrence of a defect within the process requires time to inspect,fix,and re-inspect

Average cycle time is directly proportional to the total number of defects in the process.

Product/service is delivered with no defects

No test/inspection is 100% effective in finding defects.

Delovered defects escape test/inspection within the process.

Delivered defects are directly proportional to the total number of defects in the entire process

Six sigma quality impoves customer satisfaction

Reducing the total defects in the enire process reduces:

Delivery delinquencies;

Delivery defects;

Early life failure rate;and therefore…

Increases customer satisfaction

and

Decreases warranty cost!

Process cost and defects

Reducing the total defects in the entire process:

Reduces the cycle time per unit …

Reducing WIP(Work in process)

Reducing inventory carrying costs

Resuces defect inspection,analysis,and repair cost;therefore…

Decreases “Manufacturing” cost

Cost/Quality

Six sigma has shown that

The highest quality producer is

The lowest Cost producer

The common metric: Total defects per unit(TDU)

TDU is the best measure of the over all quality of the process

TDU is the independent variable

Process yields are dependent upon TDU

Defining a unit

A “unit” may be as diverse as a:

Piece of equipment

Line of software

Order

Technical manual

Medical claim

Wire transfer

Hour of labor

Customer contact

Anything that is measurable & understandable by the person who is trying to reduce defects

Sigma,a figure of merit

TDUcould be expected to be proportional to the complexity of the unit

Complexity is directly proporttional to the number of opportunities to creat a defect

To normalize processes of different complexity, we use:

Improvement

Benchmarking

Benchmarking

Process quality levels may vary widely within a company

Implementation of the six sigma culture

The six-steps design process

Cycle time reduction

Will be coverd in detail afer lunch

Problem solving identification tool

All member of the organization should have trining in problem solving indentification tools

Flow charts

Brain storming

Pareto charts

Cause & effect diagram

Black belt tools

Process characterization

Process improvements

Graphical data analysis

Distribution analysis(graphical and numberical)

Comparative methods(graphical and numberical)

Process sources of variation

Measurement system analysis

Black belt tool(con’t)

Process control(SPC)

Process capability(Cp and Cpk)

Confidence intervals

Design of experiments

Linear regression

Screening experiments

Optimization using response surface methodology

Maanagement of the quality/continuous improvement process

Methodology to continuoisly reduce defects

Regular review of DPMO performance

Quality system review

Corporate quality council

DPMO Enables regular review of continuous improvement performance

Corporate level review

Business level review

Group or division review

Product line review

Production line review

Operator level review

Same measurement – same improvement goal

Spectrum CVD

QSR:assessment vehicle for the total organization

Sets a common goal of perfection

Drives progress to world class standards

Provides an awardreness of quality process requirments

Cross-fertilization of ideas(knowledge sharing)

Teaching tool(auditors and auditees)

Information source for registrars

Institutionalize Solutions

Corporate quality council

Quality managers of all major operations

Corporate-wide programs

Quality system reviews of all major operations

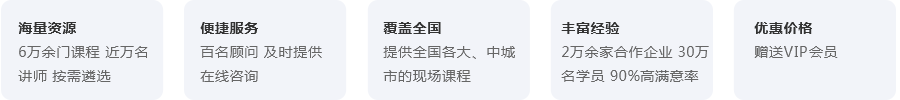

专家团由专业学养、多年实务经验、全方位互动、生动活泼实战专家、教授组成。能从一位企业管理需求、着眼经营分析及目标管理,既能结合经营管理与专业知识,却又深入浅出。同时专家团队人员还长期担任着清华大学、北京大学、香港大学、天津大学EMBA、北京理工大学EMBA、大连理工大学EMBA、西安交通大学EMBA、上海交通大学、浙江大学等国内知名大学EMBA的客座教授或特聘讲师,接受过数十家电视媒体对话栏目或论坛类专业节目的专访,学员遍及全国各地。

专业精深—— 专家团老师有多年管理的经验,结合近10年对本土企业的深入研究,整合出一整套对本土企业提升盈利能力的体系。

实力派讲师——专家团以其专业学养和多年实务经验,引入世界500强企业的先进管理方法,结合小组练习、情景模拟,案例分析、角色扮演、头脑风暴的全方位互动方式,把课程演绎得极为生动活泼,完全跳脱一般讲授的巢臼。

大师风范——专家团非常乐于与大家分享自己的研究成果,不仅常年为企业提供各种针对性强的整体财务解决方案;还应电视媒体的邀请,主讲的财务管理系列课程,受到了观众的广泛认同。